MANUFACTURING

MANUFACTURING PROCESS

T

he company is specialized in the manufacture of castings to customer drawing or pattern, with weight from a few kilograms to about 8000 kg. Items are generally supplied semi-finished or finished to drawing, heat treated, whenever required, and fully checked and/or inspected by third party agencies, according to contract requirements.

Patterns, normally wooden, polymeric or metallic, are supplied by customers and possibly adapted to company own casting techniques. Customers otherwise supply drawings or mathematic data for numerical machining and in the latter case Arno Metallurgica uses expert pattern makers capable of fabricating patterns.

Prime materials are purchased, as ingots with definite chemical composition, from qualified supplies in accordance with the specifications of reference standards. Likewise several mother alloys are available, added to heats for optimising the wanted chemical composition. Manufacturing activity is mainly formed by the following stages: moulding, melting, gravity casting, centrifugal casting, deburring and grinding, welding.

ANIMISTERIA

C

ore shop prepares cores using on purpose sands with a highly accurate control of quality and grain size.

MOULDING

V

arious stations of hand, semi-automatic and machine moulding for preparing moulding boxes, according to dimension and number of pieces.

MELTING

T

here are several crucible furnaces heated by natural gas, normally used for small medium items, while an intermediate frequency induction plant is equipped with three furnaces, capable of quickly supplying the metal for larger dimension castings.

GRAVITY CASTING

S

mall medium items are generally cast on roller conveyors, where moulding boxes are placed when coming from moulding stations and left for cooling stage. Larger dimension castings are directly cast in the moulding boxes, prepared on the floor using large sand mixers e subsequently left for cooling and shaking out.

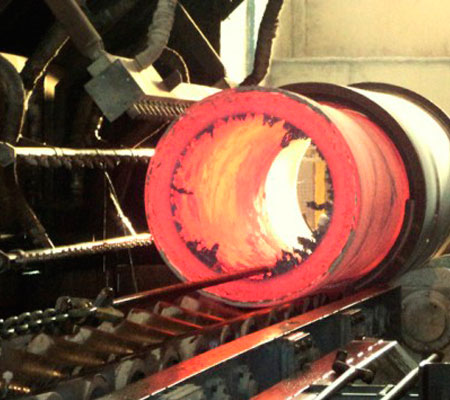

CENTRIFUGAL CASTING

C

entrifugal casting equipments are used at Arno Metallurgica as follows:

• Horizontal, mainly used for casting bearings and large dimension pipes, up to about 900 mm diameter and 3000 mm long.

• Vertical, for making small medium item, disk shaped, like gears, with about 600 mm maximum diameter and 200 mm high.

DEBURRING AND GRINDING

A

fter shaking out, castings are cleaned by metal grit blasting and then deburred, for riser and casting rods cutting, and ground, according to the need.

WELDING

T

he department operates with welders and specifications according to qualified processes, satisfying BS, ASME Section IX or other standards. Most operators are qualified under the surveillance of third party agencies, as Lloyd’s Register and others. Welds are performed according to drawing or to repair casting defects of weldable materials, as for instance aluminium bronzes

LABORATORY

A

ll processes are managed by appropriate Quality Control Plans, with the purpose of assuring the required product quality and full satisfaction or reference standards and contract specifications.

English

English